Here in the Department of Music at the University of Lethbridge we have an impressive collection of microphones. 85 microphones to be exact from amazing manufacturers like Neumann, Telefunken, AKG, DPA, Royer, Rode, Sennheiser, and Shure. These microphones see a lot of action throughout the year and require a little TLC to keep them maintained and operational.

Once a year I go through the collection to clean, repair, and test each microphone. I use a light solution of distilled water and Isopropyl Alcohol to gently wipe away dirt and clean grills. I check for any loose connectors, switches, and screws, tightening things as I go. Each microphone will then go through a process of testing its frequency response to check for damage to the capsule or electronics.

Although my method of testing a microphones frequency response is far from accurate, it’s a fast way to identify any anomalies in the response of a microphone that may require further investigation. When you have 85 microphones to test, efficiency is key.

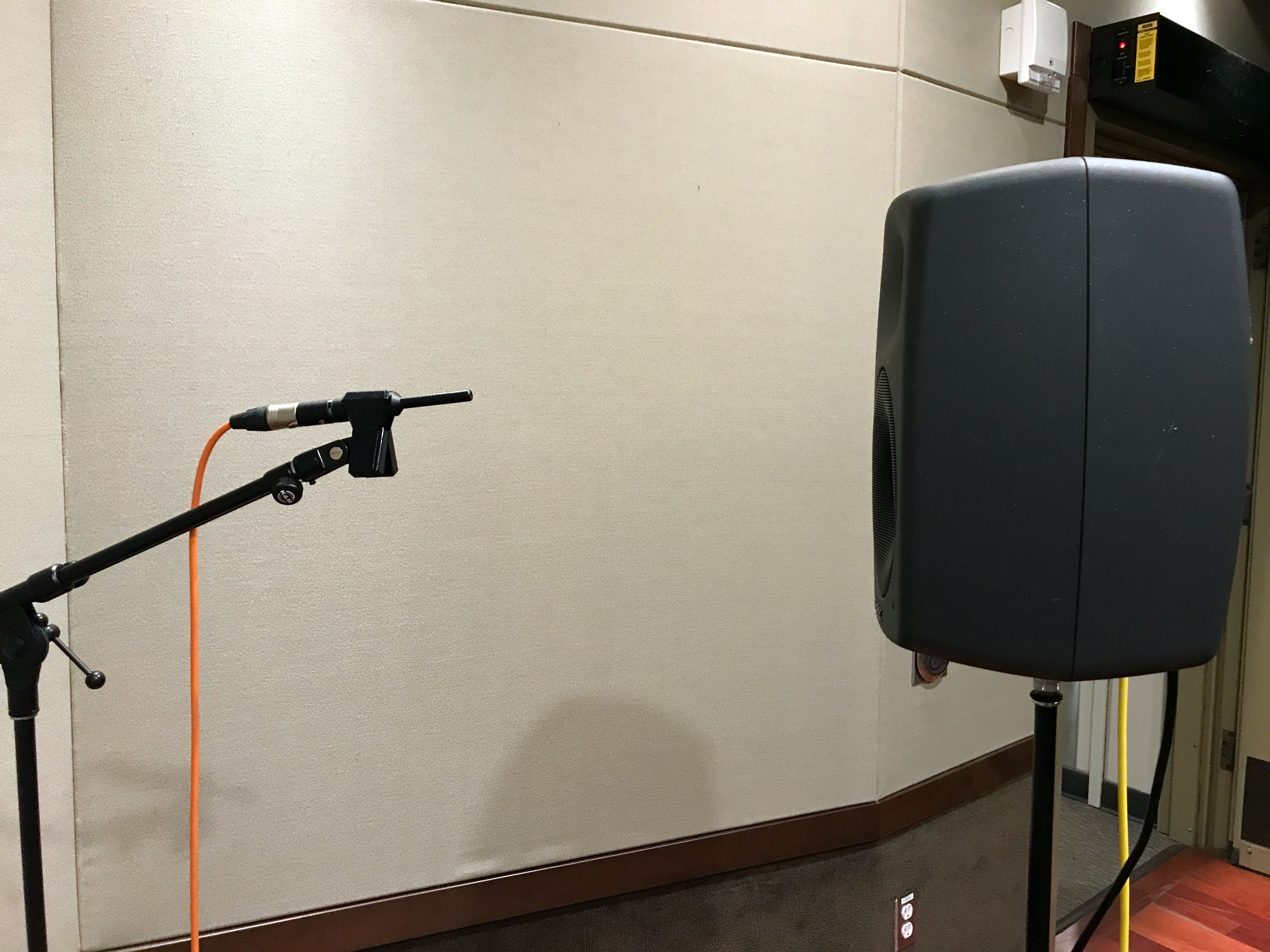

Testing Setup

- A Genelec 8040A Nearfield Monitor with it’s EQ flat.

- Beyerdynamics MM1 Measurement Mic with Calibration File.

- FuzzMeasure Pro

- Focusrite Scarlett Solo 3rd Gen

- Tape Measure

FuzzMeasure Pro, acquired by Rode, is a fantastic Audio & Acoustic Measurement utility. It’s fast and simple but is packed with some great analysis tools. For my purposes it provides customizable sine sweeps, a level meter, and an ability to compare tests.

A Genelec Nearfield monitor is placed facing a neutral corner of our studio. 30cm of distance from the speaker to the microphone capsule is maintained for each test. A frequency response is taken of the Genelec with the Beyerdynamic MM1 measurement microphone as a reference for all subsequent tests.

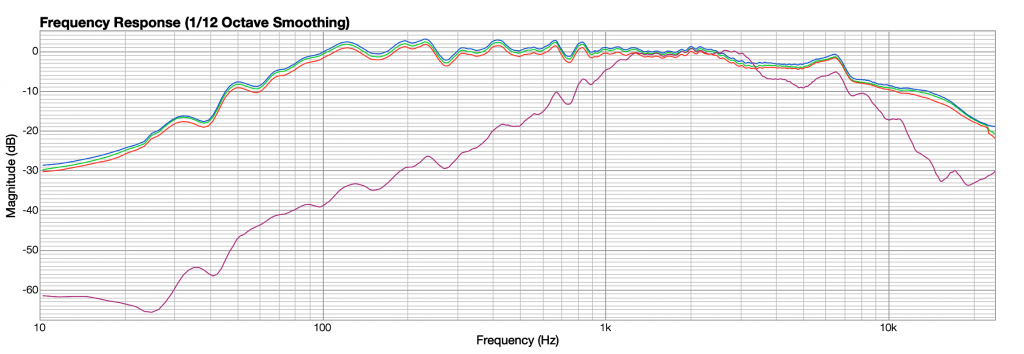

I calibrate each microphones input to 80dB with pink noise then perform a 5sec Full Range (1Hz – Nyquist) Sine Sweep. This frequency response data is used in comparison with matched pairs, previous years tests, or the manufacturers technical specifications.

Take for example the above measurements. This is 4 DPA 4006TLs. Matched pairs. These are highly accurate, pressure gradient microphones. While 3 of these microphones are almost perfectly matched in their response, there is a clear issue with the 4th. This can be seen with the sudden roll-off at 1k and 10k. These are the types of anomalies I look for when deciding which microphones may need a closer look.

While my methods may not be “scientific”, it’s a quick way to get a detailed look at the health of our microphones and spot any issues that may need further investigation.